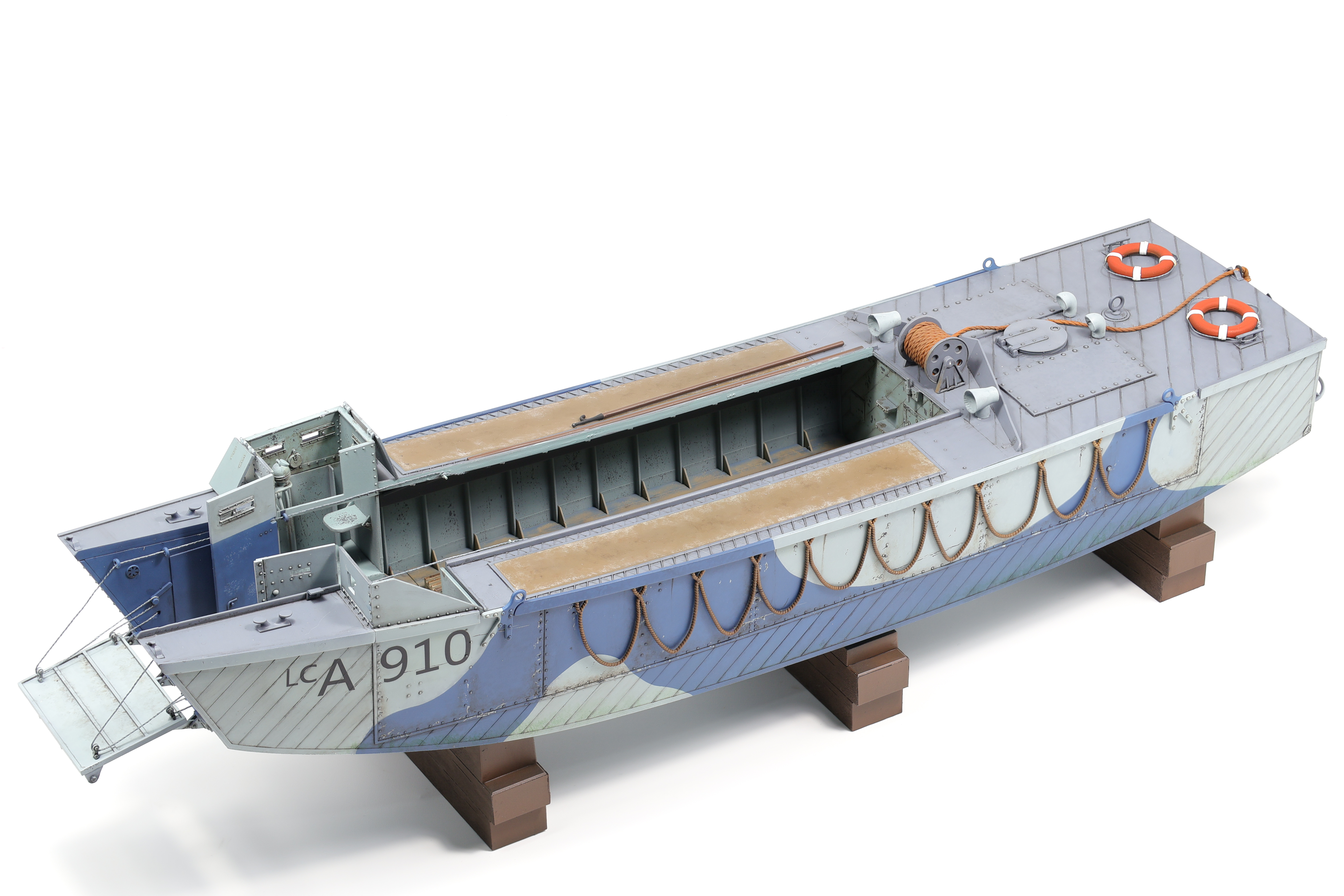

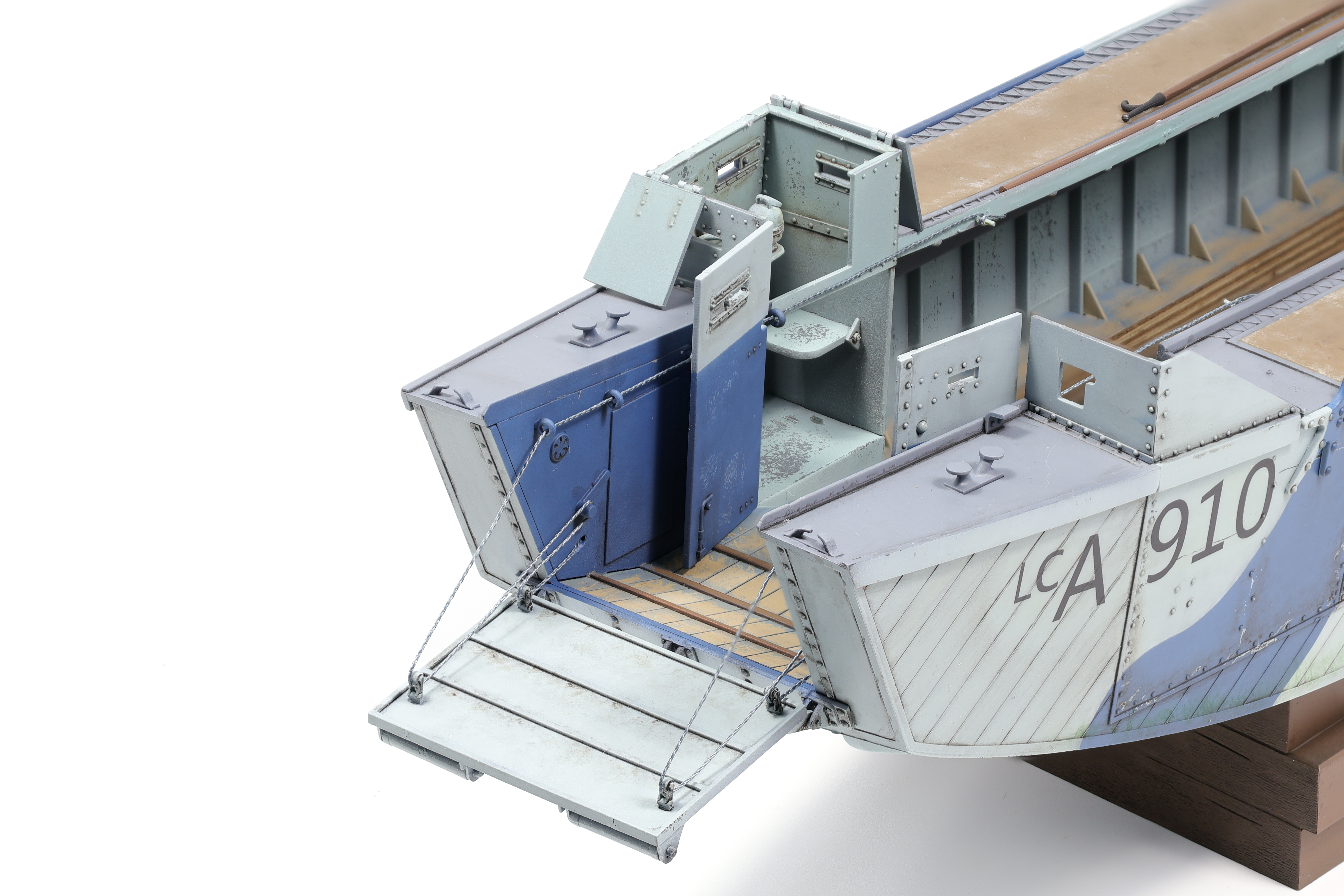

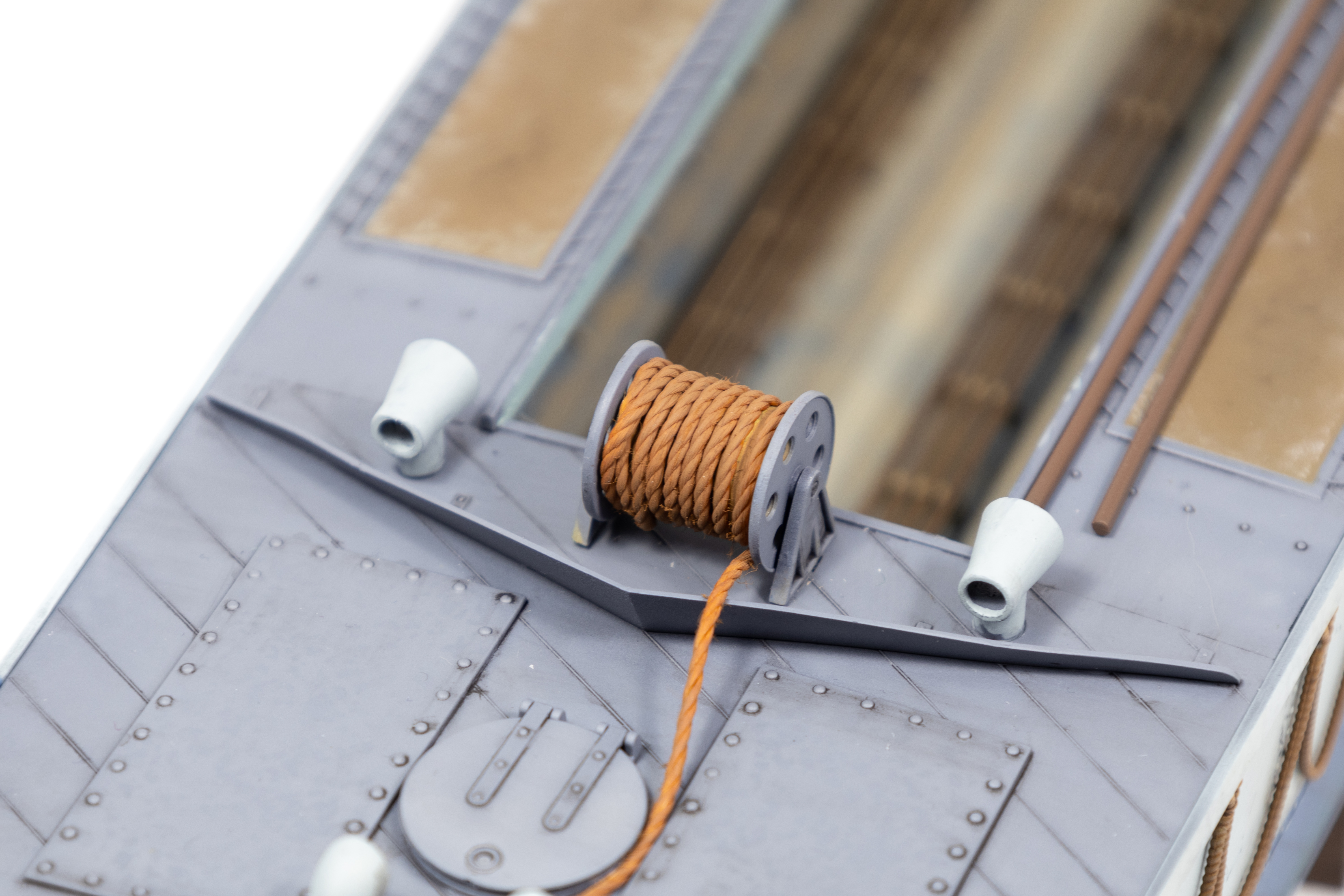

With the wrap-up of my D-Day LCA build I was able to move on to a project I’ve been looking forward to for some time now, a revisit to the infamous Tiger tank. The last Tiger I built was in 2017 (see the projects tab) and at the time it was probably the best kit I had completed. I’ve been able to grow my skillset since then and it’ll be an interesting comparison to see the two builds side by side and document my growth as a modeller.

For the build itself I picked up the excellent Dragon 6820 kit, otherwise known as the “131” Tiger. Even though it is marketed as a Tunisian variant specific to Pz.Abt 504 it can be built up as any early Tiger, especially the vehicles at Kursk. Even though it’s a 2015 release this is still a high quality kit in 2024.

Speaking of the subject I had in mind I’ll be building another Kursk vehicle (exciting I know!). This project started with the markings to be honest. I was swayed by a set from Echelon that depicted the 3.SS Pz.Rgt. “Totenkopf” during Operation Citadel. I was interested in the distinct yellow numbering of the vehicle numbers and felt that over a camo scheme of dunkelgelb and olivegrun the vehicle would pop really nicely.

With such a high potential with this build I also decided to absolutely pack it to the gills with aftermarket. The full list is below:

- Trex Studio 3d printed tracks

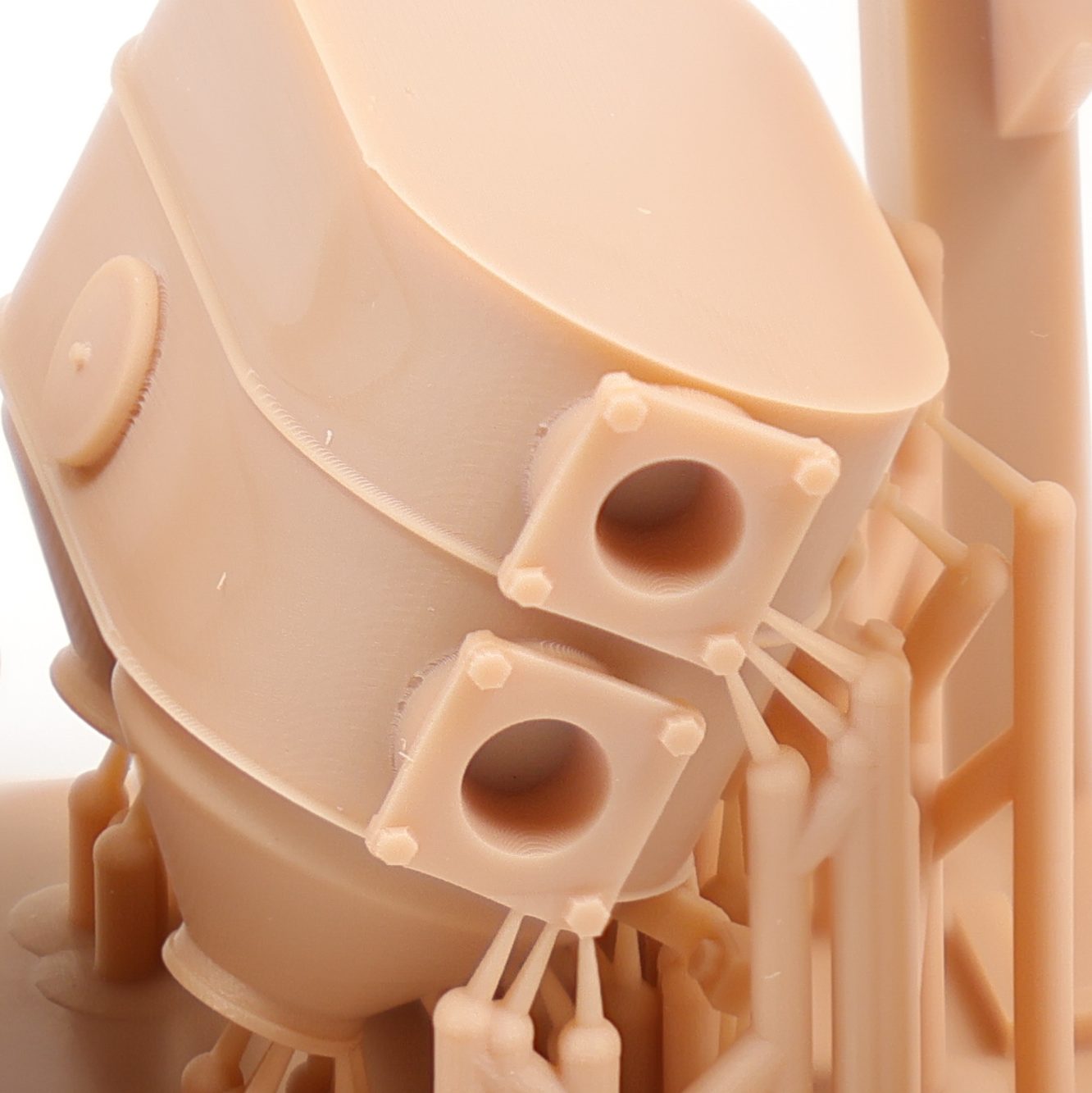

- Trex Studio 3d printed Feifel filters

- Rochm Full detail photo etched set

- Rochm 3d printed spare track holders

- Voyager brass cleaning rods

- Master metal barrel

- Aber late model brass shackle

- Alpine Minatures Panzer commander summer

- Stalingrad WSS Panzer crewman Kursk 1943

Construction was anything but straightforward on this project. Dragon can be infamous for having busy instructions and with all the accessories added in this kit, I was frequently going back and forth between different instruction sheets. Additionally the aftermarket accessories had overlap in some places and I had to decide which sets I wanted to utilize for the build. A good example of this are the tool clamps. Rochm provides photo etched tool clamps that you have to assemble. I also had a spare set of MJ miniatures 3d printed clamps in my spares drawer which I opted to use instead, as they come pre-assembled.

After a few weeks on the bench I had completed most of the hull construction. To enhance the detail on the model, I added cast texture and weld beads using Tamiya grey putty and epoxy putty respectivley. To add the weld beads, I first had to scribe out a groove and after assembling the hull I was able to work the putty inside the pre-made gaps and apply a weld texture with a scratch built tool.

I can’t lie, this phase of the build was very tedious and time consuming. Spending the time to attach then weld the dozen or so photo-etch mounting block took something out of me. Looks great at the end though. While joining the hull pieces together I found that the lower hull “bathtub” had quite a significant warp to it and needed additional prodding to allow other pieces to slot into their attachment points. The frontal armour pieces were especially useful in forcing the hull into the correct alignment. After the major construction of the hull was completed, I turned my focus to the small sub assemblies and parts that would be fixed in place on the final model.

Tool construction was up next, and as I touched on earlier I opted to use 3d printed clamps to improve this area of the model. The jack block was improved as well by scraping a razor saw along the surface to simulate a more realistic woodgrain texture.

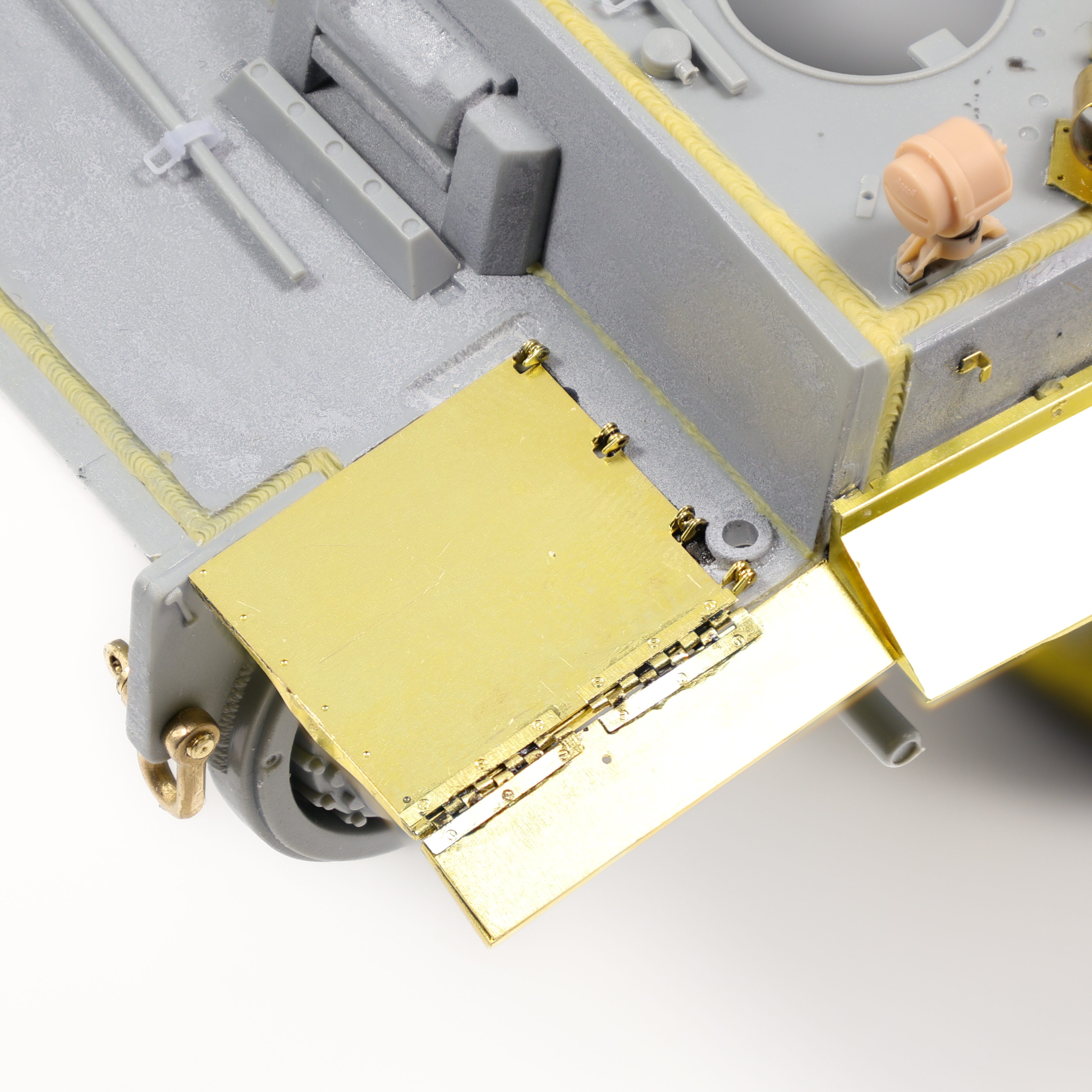

hull construction followed, unsurprisingly, with more photo-etch. I started working on the fenders and found they built up surprisingly easily. A few bends here and there and they were completed. What caused me issues however were the hinges on the front and rear fenders. Each fender required two complete hinge assemblies with two parts each. Suffice to say, this was a tedious process and somewhat time consuming. Was it worth it? You be the judge:

The side fenders were pretty straightforward and went together a lot better. I did have some issues affixing them to the hull as the mounting blocks were a bit off but all together I think they went on very well. I opted to remove some fenders on the front of the tank to add some visual interest as well.

Quite a bit of work was done to the rear of the vehicle as well including test fitting the T-Rex studio Feifel filter along with some stowage from Panzerart and Ultracast. I also tested fitted the tow cable to see what positions worked in relation to the planned stowage.

I also neglected to attach one of the headlights and S-mine launchers as from my reference photos I could tell that the specific vehicle I wanted to document was missing these features on the right side.

All in all this build so far has been unnaturally slow for me. I’m almost a month in and it feels like it’s taking forever yet I know that slow and steady is the required strategy for this project. There are too many possible issues that could creep up if this project is rushed. With so much aftermarket being included in the build it’ll be easy to miss things but as long as I take my time then I’ll be able to finish this project to the standard I’m aiming for.