For the last little while AFV Club’s Pakwagen has been a priority for me to build. There are a few reasons for this, namely I just think it’s a cool subject and I’ve been meaning to build one for a while now. There’s also the fact that I’m a bit out of practice when it comes to painting and weathering German vehicles and since I have a few slated to be built this year, this kit will serve as a nice test run prior to starting those planned builds.

I had intended for the construction phase of this build to be as smooth and painless as possible. I didn’t want to invest a ton of time building the kit because like I said, the focus was supposed to be on the painting and weathering. Unfortunately for me, AFV Club had other plans.

In short, the kit doesn’t fit well at all and has significant engineering issues. This entire process has been frustrating to say the least. It’s been so bad I’ve considered swearing off this brand all together, however there are a few Israeli Shot Kal’s they offer that may tempt me. Bottom line however, I’m not buying another AFV Club kit for a while.

Construction begins assembling the lower hull and suspension components. There’s nothing to write home about here, and the fit for the suspension arms is vague at best. To my surprise the whole frontal steering and suspension assembly section fit together well and was level when completed. Of particular note was how the drive wheels (Not the steering wheels) fit together. AFV Club has you completely sandwich them together (Step 3) and it takes a significant amount of force to do so with one of mine even cracking under the pressure. it’s amazing this was the solution that was some up with.

The dashboard fits together alright and I opted to add some wiring despite the fact that it won’t ever be seen. Fitting the dashboard to the hub however is tricky and you really have to make sure that it’s seated well because if it’s not that will impact how the upper hull will fit. Next I filled out the various fittings for the main compartment and by far the cradle for the Pak 40 (assembly J) was the worst subassembly of the kit so far. I opted to assemble the thing attached to the hull then glue the parts together to ensure the final product will fit properly. I thought that this was a good idea until I actually tried to assemble it and here’s what went wrong:

- Part Ho2 is too big and will cause the legs (Ho3 and Ho4) to bow out.

- Part Ho5 doesn’t fit it’s attachment point and it’s not close.

- Part Ho1 has “steps” for the legs to slot into but these “steps” are more like “curves” and it’s impossible to get concrete fit.

- The pins for the entire assembly used to fit into the hull are incredibly small/weak and you’ll shear them off easily.

- The entire assembly is too tall and you need to remove 1-2 millimetres from the top to allow the upper hull to fit.

This kit had various other fit issues such as the engine access doors, the exterior storage doors, the rear doors for example. Now that I think about it, virtually all the doors in this kit had problems fitting. AFV Club, how hard is it to make a rectangle fit in a hole?

With all these issues I was dreading working on the Pak 40 Anti-tank gun. With numerous fiddly parts I did not have a ton of hope with how it was going to go together. The answer? Not great, not terrible. Really, it wasn’t the worst, and was better than other parts of the kit. It wasn’t great by any means but the end result is a somewhat good looking Pak.

For this build I used a set of 3d printed tracks from DEF Model and while I’m typically wary of 3d printed products I don’t have direct experience with these went together beautifully. They came off their supports with little to no effort with not a single link broken or unusable. Additionally, they went together great and just snap together. If there are any downsides to these they are as follows: first, since they are snap fit they tend to deform under tension and one “pin” will slip out (without coming apart all together). Second, I don’t think they fit the model that well as they have to be posed under high tension or fairly slack with the addition of one link. Despite these issues I don’t regret picking these up and always like to try new tracks.

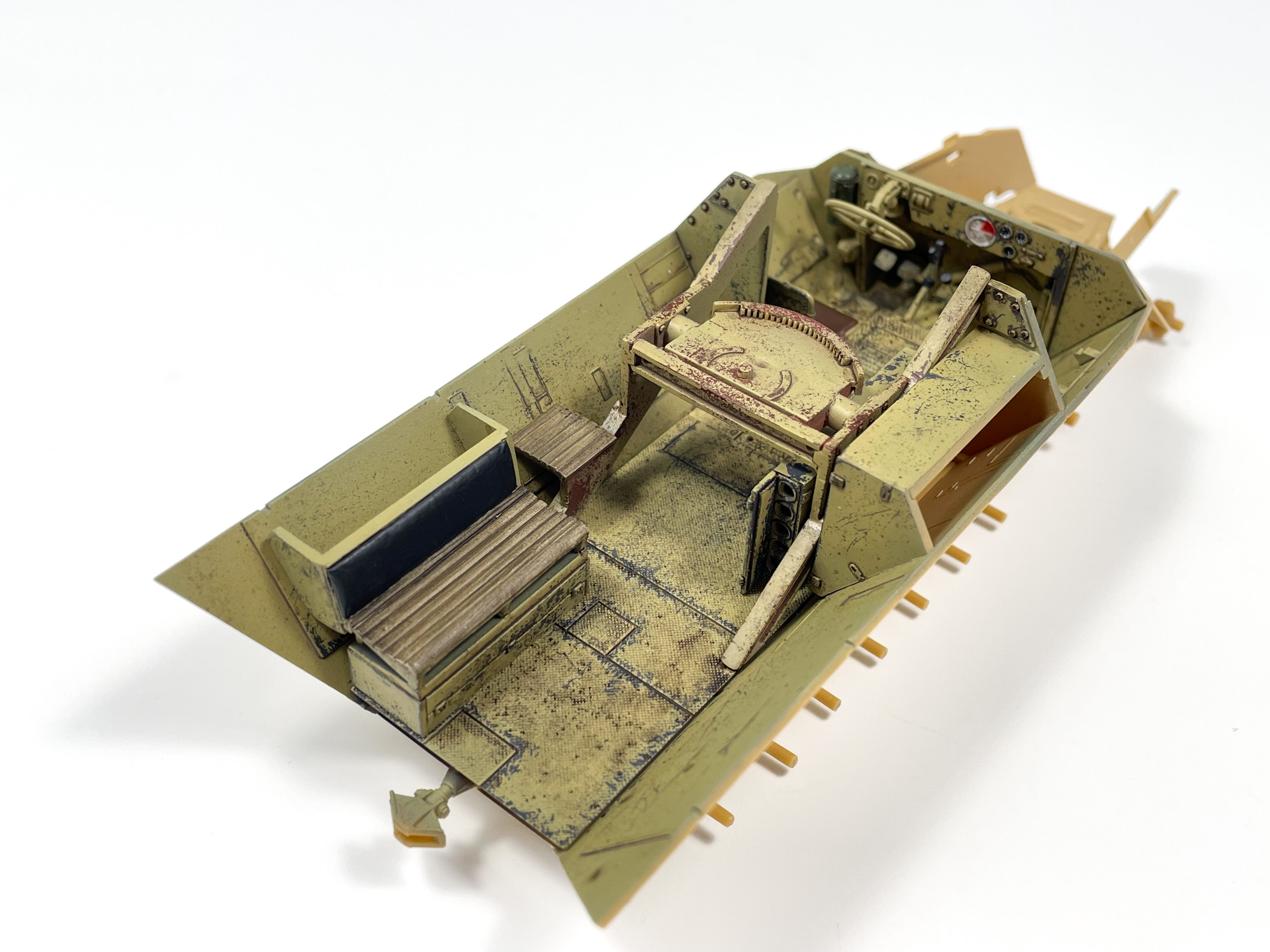

Construction had to take pause here as I needed to complete the painting of the interior before moving forward. The assembled vehicle would have zero space for any kind of painting or weathering of this area when built up so I decided to finish this task now. I knew I would be painting the interior in German dark yellow and opted for German grey as the undercoat chipping layer, seeing as the exterior of the vehicle would be chipped with red-brown.

To be honest the chipping fluid method did not work as well as well as I intended. It was difficult to get the paint to chip the way I wanted and I ended up with small flakes coming off instead of larger, more controlable chips. I used Tamiya dark yellow thinned with the Tamiya acrylic thinner and I’ll have to investigate more into how to get the results I’m looking for. All in all I’m not too disappointed because A; this area won’t be hugely visible and B; I got to practice doing hand made chips. I think this went ok seeing as I have next to no experieince creating the chipping effect this way.

I also tried making some basic woodgrain texture using oil paints. It’s quite an interesting technique and somewhat straightforward. I painted the wood parts in Tamiya Buff, and then using a dark brown oil paint colour I streaked the paint across with a dry brush. This creates visible brushstrokes that simulate woodgrain that looks very realistic in scale. I like how this turned out!

At this point I sealed the interior with a coat of VMS satin varnish prior to going further with the weathering. I next used oil paints for a pin wash but also to create some surface definition on the vehicle floor. I did this to represent general dirt and grime that would get caught on the grippy steel surface. It’s important to mention that this was a very general approach and in this phase I didn’t pickout specific details (aside from the pinwash). Additionally, I speckled on some MIG enamel weathering product “fuel stains” and “Oil and Grease stains” to create points with a little more contrast to the dark yellow base coat. I didn’t want too much contrast however and I used a brush damp with enamel thinner to slightly feather the drops to create a more subtle gradient.

This was largely the end of the general weathering and a sealed the model in a coat of alclad flat before moving on to more specific, focused weathering effects. For this stage I’ve been really drawn to three products in particular, MIG’s “Fuel stains”, “Oil and Grime stains” and “Engine Grime” The names of these products can be deceiving as they are very versatile enamel products that can be used in many different applications. In this stage of the weathering I would apply one of these products near a detail I wanted to highlight and then stipple the slightly dry product with a brush damp with enamel thinner to create a gradient and blend the stain into the model.

Overall despite some atrocious fit issues, AFV Club’s Pakwagen is slowly shaping up and is looking fairly good at the moment. More posts to come on this subject!