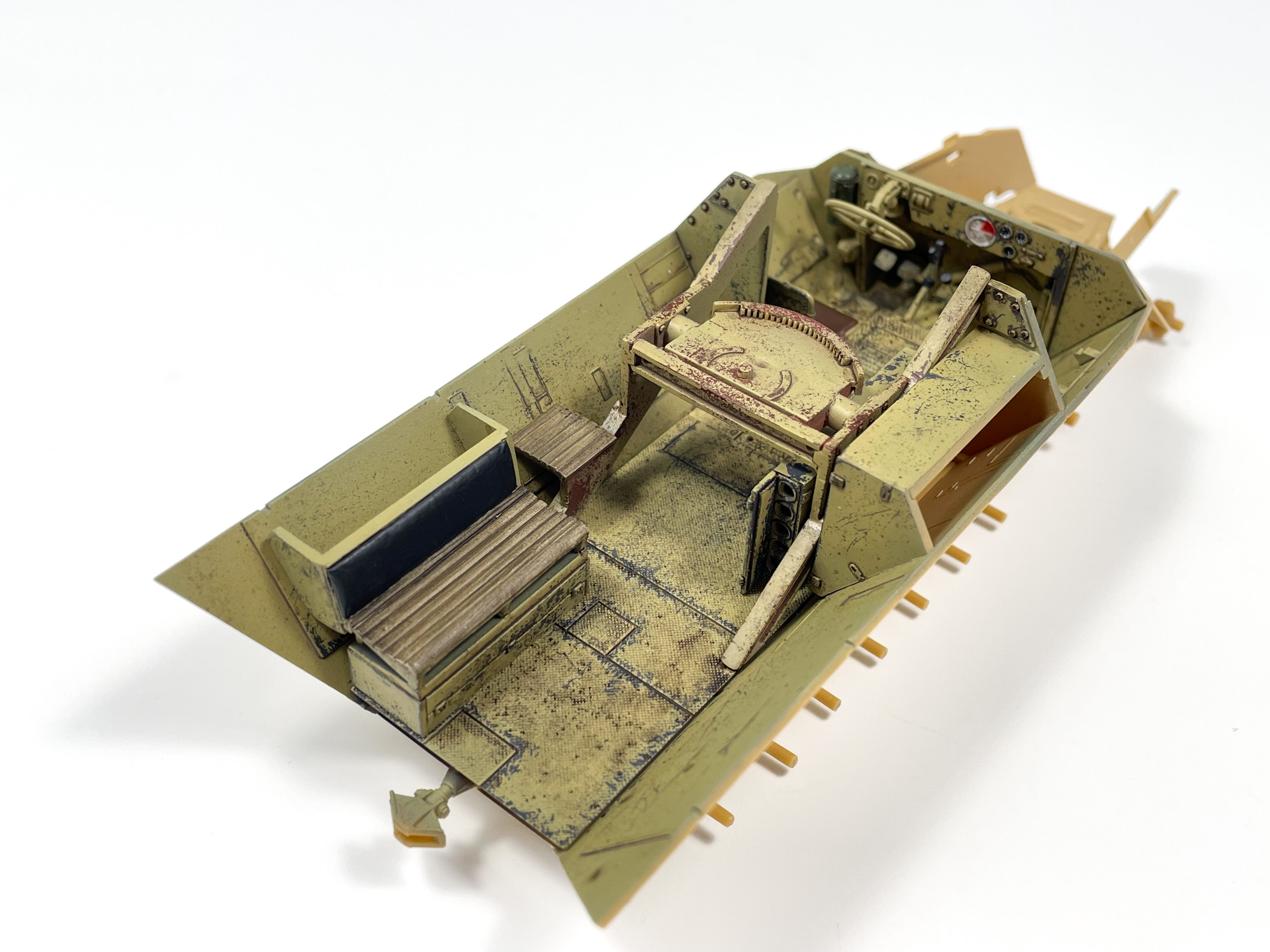

With the completion of the interior of AFV Club’s Pakwagen, I could move on to a phase of the build I was really looking forward to, the painting and weathering. It has been a long long time since I’ve done a German camouflage scheme (I don’t count the DAK Pz.III I did last year) and they are undoubtedly my favourite kind of paint job to recreate.

I wanted to simulate some hairspray chipping, so I opted to use Tamiya LP-18 “Dull Red” and to be honest, I’m not a huge fan of this shade. It’s a little too red in my opinion and almost looks like blood. For my next kit to utilize this shade I’ll probably add in some dark brown to tone it down a bit.

Following the primer red I hit the model with a coat of hairspray before moving on to the camouflage colours. Tamiya released a new set of German camouflage colours some time ago and I wanted to try these shades out and see if I liked them enough for future builds. I used XF-88, 89 and 90, Dark Yellow 2, Dark Green 2 and Red Brown 2 respectively for the base colours. I throughly enjoyed how the Dark Yellow and Dark green shades came out however I have my doubts about Red Brown. For starters, it can look quite green in the bottle and unless you spray quite an opaque layer over dark yellow the edges will look somewhat orange to my eye. I’m not sold on this shade and may look elsewhere for future builds.

I unfortunately don’t have any more “in progress” photos of the painting process as I was fairly busy during the couple of days it took to apply the camouflage scheme. I also added some excellent dry transfers as the unit markings. I loaded up with some of Archer’s dry transfers after they closed down and I’m really glad I did, I’m very happy with how they perform and look.

Overall, the initial painting stage went very well and I sealed the model with a coat of VMS Satin varnish to protect the previous work and prepare the model for an oil wash. I used the Bitume shade oil paint as a general starting point for the weathering as it it a good base to build off of with more focused weathering effects.

Following the pinwash, I started some streaking effects with AK’s “Winter streaking grime” I often don’t pay much attention to what the name is on the label and the dark brown shade of this product contrasted well with the dark yellow main coat.

I also unmasked the interior as I had laid down my last (anticipated) coat of matte varnish. I’ve been aiming to get out of the habit of over-sealing my models between weathering steps as I’ve come to realize that too many varnish layers can really diminish the realism and overall look of the final product. I think that the vertical streaking effects done help to break up the lines of what is a very angular vehicle and enhances the overall look.

Weathering the main gun also progressed quite smoothly with a few applications of oil and grime washes. I wanted the breech area of the pak40 to both contrast with the dark yellow interior but also be subjected to the same level of dirt and grime as the rest of the interior. I’m still not 100% satisfied with it and I may do more work with this area of the build but I’ll have to see.

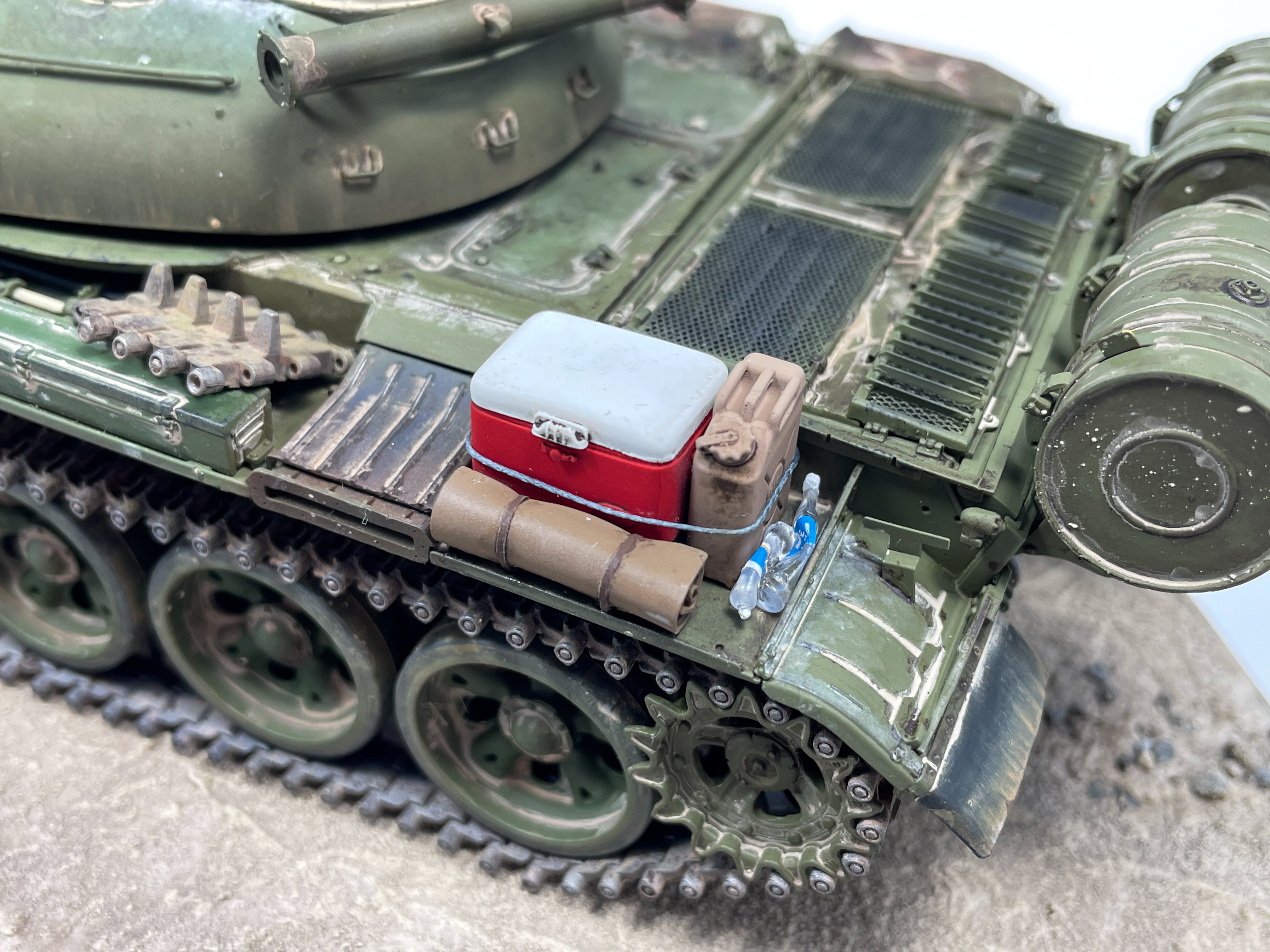

I then moved on to the mud and dirt application of the build. Seeing as this vehicle would be situated during the spring thaws of 1945, it would make sense that the vehicle would see a liberal application of mud in and around the running gear. Still, I had to be careful as I wanted to strike a balance between almost black (winter) mud v.s more brown (summer) dust/dried mud. I’ve begun experimenting a lot more with enamel dusting and it’s quickly becoming a favourite technique of mine. The general process is as follows:

- Spray a highly diluted layer of enamel paints in areas where dust may accumulate.

- Let the enamels dry for approx. 10-15 minutes.

- Brush a light layer of enamel thinner onto the painted area.

- Streak the brush in a vertical motion until the painted enamels begin to shift in accordance with the brush strokes.

- (Optional) add another light coat of enamel paint to depict dust/dirt that has not been disturbed yet.

Next I applied a liberal application of mud to the underside of the vehicle and the running gear. To do this I applied AK’s “Damp earth” and “Fresh mud” fairly sloppily. I then sprinkled two shades of pigment, MIG’s “Track Brown” and Abteilung 502 “Trench Earth”. These various shades were used to provide variation in the final product. While I think that the final result looks good, It is fairly uniform and I’ll have to work on achieving greater contrast between different shades of mud and dirt.

These comparison images really show how powerful the enamel dusting and mud splatter techniques can be. An area I wanted to target was the vertical plates with the storage lockers. Seeing as this area of the vehicle would see regular use by the crew and would be exposed to mud and dirt being flung up by the tracks I made a dedicated effort to single out this area for a little more attention than other parts of the model. The effects can further be seen by comparing the unweathered balkenkreuz in the before and after images.

Despite my minor issue with the lack of contrast in the mud tones, I really do like how this area of the build turned out. To my eye, I think that the end result is realistic and ascetically pleasing. I’m looking forward to adding mud and debris to my future models!

That’s it for this update! Really happy with how the painting and weathering process has turned out so far. There’s not a whole lot left to complete on the vehicle itself but there is still a fair amount of work to do on the accompanying figures, stowage and diorama base I have planned for this kit. Thanks for looking!